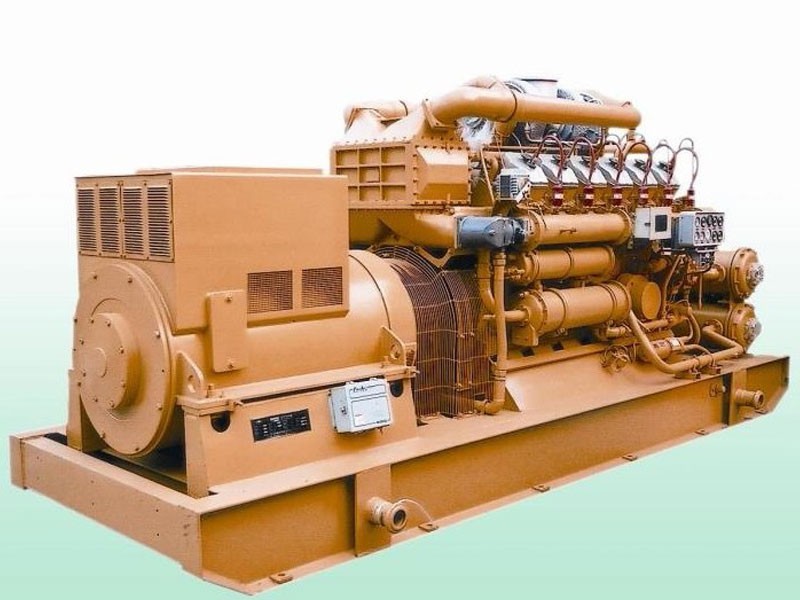

Gas Generator 3.5 MW With Two Years Warranty

- CNPC JCPC

- China

- 5-8 Months or negociated

- 200 sets/year

1. We have natural gas generator ranges from 300kw to 5000kw. This generator was mainly designed to meet the demand for long-distance pipeline compressor, offshore drilling plantform, large-scale gas power station and etc.

2. The gas generator has the features of high pressure, high power, high efficiency, low emission etc.

3. The gas generator thermal efficiency is more than 44%.

4. Knock control technology and explosion pressure monitoring.

5. Service center in South America and some other country

1.1 Genset brief introduction

3500kW natural gas generating sets (3500GF-T) are powered by model 16V26/32T gas engine produced by our company.

It has the features of accurate voltage regulating, good dynamic performance, less voltage waveform distortion, high efficiency, compact structure, easy to maintain, low speed, good reliability, long life operation and cost-effective.

1.2 Genset technical parameters

Model of genset | 3500GF-T |

Model of engine | 16V26/32T |

Coupling method | Flexible coupling |

Rated speed | 900 (r/min) |

Rated power | 3500/4375 (kw/kva) |

Rated voltage | 6300/11000 (v) |

Rated frequency | 60 (hz) |

Rated power factor | 0.8 lagging |

Voltage regulation | Automatic |

Supply connecting | 3 phase 3wire |

Governor | HEINZMANN(GERMANY) |

Control model | Remote electric control, Hand control |

Starting method | Pneumatic starting motor |

Cooling method | Water cooling system with upstanding radiator |

Overall dimension L×B×H | 9400×2900×3700 (mm) |

Net weight | 70000 (kg) |

Section2. Gas engine

2.1 Engine brief introduction

The 26/32 series natural gas engineprovided by our company is heavy duty designed, four-stroke cycle, stationary type, water cooled and of the manufacturer‘s qualified design for continuous operation required. The 26/32 series natural gas engine is exhaust turbine,16cylinders, V-type engine.

The crankshaft, flywheel, piston connecting rod and other related reciprocating parts are balanced and the engines provide counterweights to ensure minimum practical unbalanced forces and moments.

The engines assembly includes parts, accessories and auxiliary equipment required for installation and satisfactory operation, under specified operating conditions. All designed and constructed of materials are suitable for the service requirements and arrangements could minimize fire hazards and vibration damage.

The 26/32 series natural gas engine features high power density, high efficiency, light weight, compact structure, long overhaul period, and maintenance-friendly design. The engine adopts multi-point injection technology, and the combustion organization method is injected into the main combustion chamber after being ignited by the pre-chamber gas to increase the ignition energy, and the Miller cycle and air-fuel ratio are precisely controlled to achieve lean combustion. Through the mechanical check valve, the pre-chamber inlet air is controlled and the check valve opening pressure is 130 mbar. With the new engine control system, the engine's air-fuel ratio control, knock detection and misfire detection, and engine operating parameter detection and safety are achieved, and could meet HSE requirements.

2.2 Technical parameters of gas engine

Model of engine | 16V26/32T |

Rated Power | 3780 (kw) |

Rated Speed | 900 (r/min) |

No. and layout of cylinders | 16-cylinder, V-type |

Type | Four stroke, water cooled, turbocharged and after-cooled, pre-combustion chamber, spark plug ignition, mix before compressor, multi-point injection |

Type of combustion | Lean burn |

Brand of turbocharger | ABB |

Gas inlet pressure | 4~6 (bar) |

Gas consumption | ≤0.23 (nm3/kwh) |

Specific oil consumption | ≤0.5 (g/kwh) |

Thermal efficiency | 44% |

Type of lube-oil | KCN 7805 (sulfur content<=200mg/m3) KCN 7810 (sulfur content <=460mg/m3) |

Oil sump capacity | 1760 (L) |

Idle speed | 400 (r/min) |

Bore | 260 (mm) |

Stroke | 320 (mm) |

BMEP | 16.5 (bar) |

Total displacement | 272 (L) |

Noise | 115 (db) |

Exhaust temperature(before turbine) | ≤620 (℃) |

Direction of rotation | Counter-clockwise(facing to flywheel) |

Emission | 0.5@5%O2 (g/nm3) |

Lubrication method | Pressure and splash lubrication |

Overhauling | ≥40000 (h) |

Manufacturer | CNPC Jichai Power Company Limited |

According to the standard of GB/T 6072 (idt ISO 3046), The standard environment conditions are: atmospheric pressure: 100kPa, relative humidity: 30%, ambient temperature: 25 degrees Celsius, low heat value of gas: 36MJ/Nm3, max. load,. Otherwise, the engine power shall be corrected through conversion.

Section3. Alternator

3.1 Alternator brief introduction

Our generator use JFG series high voltage alternator,the alternator conform to applicable IEC 60034-1 requirements, GB755 standards.

JFG series generator has degree of protection IP23 and adopts IMB20 installation type.

The generator comprises the main machine(revolving-field machine with cylindrical rotor and damper windings),exciter(revolving armature machine)and excitation equipment. The excitation system mainly adopts currently the world’s most advanced DECS100 or UNITROL 1000 digital automatic voltage regulator which is produced by BASLER company or Switzerland ABB company, By using the permanent-magnet auxiliary exciter system, the main generator, the permanent-magnet auxiliary exciter and digital automatic voltage regulator perfectly matched that constitutes the high quality and excellent-performance generator.

3.2 Technical parameters of alternator

Main technical parameter | |

Type | JFG series (SIEMENS Technology) |

Rated power | 3500/4375 (kw/kva) |

Rated voltage | 6300/11000 (v) |

Rated frequency | 50 (hz) |

Power factor | 0.8 (lagging) |

Excitation model | Brushless |

Wiring method | 3 wire, 3 phase, star type |

Number of pole | 8 |

Rated speed | 900 (r/min) |

Voltage regulator | ABB, Unitrol series |

Excitation mode | Brushless excitation, PMG |

Insulation class | Class F |

Protection class | IP23 |

Cooling | Fan cooling(IC01) |

Duty | Continuous work(S1) |

Bearing type, No. | Rolling bearing, 2 Pcs |

Installation method | IM B3 |

Moment of inertia | 360 (kg.m2) |

Efficiency | 97% |

Machine weight | 12100 (kg) |

Winding temperature measurement | PT100, 2 units per phase, one use and one standby |

Bearing temperature measurement | PT100, 1 unit for front and rear bearing |

Anti-condensation heater | AC220V/315W, 1 pc |

Main performance index | |

Stable voltage regulating rate | Single running: ±1% Parallel running: ±2.5% |

Instantaneous voltage regulating rate | -15%~+20% UN |

Waveform distortion rate | <2% |

Over load | 1 hour operation time at 110% rated power (6 hours as a cycle) |

Unbalance load | 0.2 |

Over current multiple | 1.5IN, 2 minutes |

Ability of maintain short-circuit current | The excitation system can provide continuous current of two times of rated current, duration 5s, the alternator must be unloaded. |

Short circuit calculation parameters | |

Direct-axis synchronous reactance | Xd=2.52 |

Quadrature-axis synchronous reactance | Xq=2.50 |

Direct-axis transient reactance | Xd’=0.187 |

Direct-axis subtransient reactance | Xd’’=0.094 |

Quadrature-axis subtransient reactance | Xq’’=0.113 |

Negative sequence reactance | X2=0.103 |

Zero sequence reactance | X0=0.052 |

Stator winding resistance | r1=0.009 |

Direct current component time constant | Ta=0.036s |

Transient component time constant | Td’=0.148s |

Subtransient current time constant | Td’’=0.003s |

Short circuit ratio | KC=0.45 |